16th August 2022

Everyone knows the best laid plans can go wrong. No matter how good your equipment, or how well prepared you are, it always pays to expect the unexpected.

Unforeseen electrical and mechanical failures are a fact of life, as anyone who works in construction and water industries will know all too well.

The increasing shift to the use of more eco-friendly electric pumps, which Selwood is proud to be at the forefront of, also leads to an increased likelihood that external electrical failures can affect a project.

Of course, when a pump stops pumping, water will rise – potentially leading to a number of adverse outcomes. These may include flooding and potential site safety risks, the reputational and financial costs of resulting environmental damage, the risks of fines for breaches and the possibility of water backing up and causing more damage to the system.

All of these are outcomes that you would prefer to avoid – so you’ll know that you always need a backup plan to ensure that whatever you are pumping, and where you are, continuous flow is maintained in the event of a power outage or mechanical failure.

The question is – what kind of backup is best?

The problem with generator backup alone

For decades, traditional pumping station design has included the use of backup diesel generators which kick in if the main source of power fails. More recently, the diesel is often substituted for HVO fuel which is cleaner burning and more environmentally-friendly, but the principle is the same – in the event of a failure, the main control transfers power to the backup generator which seamlessly takes over, keeping the system operational.

That’s fine if – and it’s a big “if” – it’s the power source that has failed. However, in the majority of cases the failure is mechanical.

Our monitoring shows that 14% of pump failures were the result of power outages causing electrical failure, while a far more significant 86% were switchgear or pump related mechanical failures.

A backup generator simply won’t solve the problem if the failure is mechanical – so you’re out of action until maintenance can be carried out to fix the problem, or new equipment is brought on site.

A better backup

Increasingly, we’re seeing that customers prefer to avoid the downsides of generator-only backup and choose instead a more effective solution.

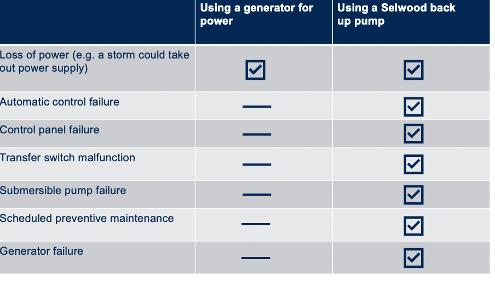

This comes in the form of a complete, independently powered backup pumping station that covers not just power loss but a full range of other complications including failures of automatic control or control panels, individual pump units going down, transfer switch malfunction and generator failure.

This also provides an easy backup for the complete system for when scheduled preventative maintenance takes place.

This automatic, self-priming backup can be fuelled by diesel or greener HVO and is automatically activated by sensors which detect rising water or sewage levels in the wet well caused by the failure of the primary pump. After priming, the system pumps the required flow as a direct replacement for the primary, so there is no downtime.

Selwood can provide float-controlled pumps which ensure the backup only operates when needed, reducing fuel costs and emissions and keeping the water at the required level. It can then auto-shut off when power is restored or the mechanical problem is resolved and the primary system resumes operation.

Total peace of mind

Using a Selwood complete backup in this way offers double protection, against electrical or mechanical failure, or both – just when you need it the most.

All pump backups can be housed in our Super Silent canopy, minimising noise for local residents and people working nearby.

To find out more, contact us.