23rd May 2022

Can you hear a popping sound or what sounds like marbles coming from your pump? If the answer is yes, you may have a cavitation problem.

Tiny bubbles created by changes in pressure inside pumps collapse and can erode components over time. Pump cavitation can be strong enough to cause serious damage to your pump.

Why does pump cavitation occur?

Pumps are designed to work with a full flowing water supply but in some cases there might not be enough flow, and therefore pressure in the system.

The inlet or suction side of a pump is the lowest point of pressure in a pump and where cavitation can happen.

Cavitation can occur in all types of pumps but is more common in centrifugal pumps – these types of pumps depend on changing pressure inside the unit to create a vacuum, pushing the liquid into the unit as opposed to pulling it in.

The two types of cavitation are suction and discharge:

Suction cavitation is when a pump is under low pressure or high vacuum conditions. If the pump is starved or is not receiving enough flow, bubbles will form in the eye of the impeller.

Discharge cavitation is when a pump’s discharge pressure is extremely high – in other words the pump is running at less than 10% of its best efficiency point (BEP). The high discharge pressure makes it difficult for fluid to flow out of the pump, so it circulates inside the pump. The liquid gets stuck which causes a vacuum and the formation of bubbles.

How to recognise pump cavitation

The sound you hear is likely going to be the most obvious indicator of cavitation. It’s often described as marbles or gravel moving through the pump or pipes.

In the case of a submersible pump – whether hydraulic or electric – pump cavitation is harder to detect (but also rare), which is why we suggest looking out for vibration, seal/bearing failure, impeller erosion and higher than usual power consumption.

You may also find the temperature of your pump increases with cavitation because you are pumping dry and building vapor pressure which causes the motor to overheat. This not only reduces motor life but potentially will cause damage to the impeller and pump itself.

How to prevent pump cavitation

Select the right pump for the job

One of the best ways to prevent pump cavitation is to properly operate a pump best suited for your application, and to work this out you need to consider its Net Positive Suction Head (NPSH).

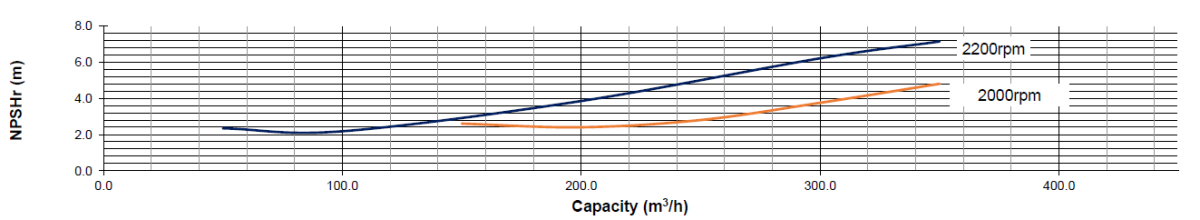

Net Positive Suction Head Required (NPSHr) is the minimum pressure required at the suction port of the pump to keep the pump from cavitating.

Selwood pumps are typically 8.8m maximum suction lift, so to work out the maximum allowable suction head you to need to subtract NPSHr from 8.8m.

The graph below shows an example of a D150 pump. The higher the flow, the less suction head is available since you would need to remove NPSHr from 8.8m max suction head.

Check pump curves

Pump curves tell you how much net positive suction head the pump requires, so check your pump’s performance curve to ensure it has the right specification for your application. Use a pressure gauge and/or a flow meter to understand where your pump is operating on the curve. Running a pump as close as possible to the best efficiency point also heavily reduces the chances of cavitation.

Calculate the pump curves for your project using our handy tool.

In many cases moving your pump closer to the fluid source and removing as many bends and valves as possible can correct the problem because each component you add will cause more pressure to drop.

Regular pump maintenance

We recommend regular maintenance of your pump to ensure it performs as it should and to keep cavitation at bay:

- Blocked pipework can be a cause of cavitation, so check it is clean or clear any blockages.

- Check filters and strainers as if they are dirty or blocked they can generate pressure buildup inside the pump.

- Look for cracks or collapsed piping/hoses that will disrupt the system.

Also consider whether there are too many fittings attached to your pump suction pipe and if the suction pipe diameter is too small or long? Is the pump installed too high above the fluid source?

Cavitation is a common problem in pumping systems, but choosing the right pump for your application and with regular maintenance, damage to pumps and their impellers can be largely avoided.

Call our pump rental team today for advice on pump repair, maintenance and finding the most suitable equipment for your needs.

0333 014 2000